|

Auto Die Mounting

|

|

Purpose:

To mount the wafer into a mylar tape and attach to metal frame.

Equipment Type:

- K&S ring

- Disco ring

- Wafer ranges from 2”, 3”, 4”, 5”, 6” & 8”

Manufacturing Capabilities:

- PCB Sawing

- Molded Package Sawing

- Ceramic Substrate Sawing

- PZT wafer sawing

- SiC , GaAs Wafer Sawing

- Electrical test on Vf, Vr and LOP

- 30x -100x wafer inspection

- Provide 100% Die Visual services

|

Die Sawing and Mounting

|

Purpose:

To singulate units from a wafer or substrate form.

Equipment Type:

Disco / TSK (Straight & Bevel Cut: Single/Dual Head Spindle / Laser Saw)

Manufacturing Capabilities:

- K&S ring and Disco ring

- Wafer Thickness from 0.05mm to 0.32mm

- Saw street: as small as 0.02mm to 0.074mm

- Spindle speed : 65k rpm

- Die size – as small as 0.178mm x 0.178mm to 2.30mm x 2.03mm

- Wafer size 50mm to 203mm

- Qty per wafer : up 55k dies / wafer (11 hrs sawing)

- Sawing conditions capabilities : DI Water resistivity with CO2 bubbler <1M or >10M, RO, H2O2, Triton-X & Diamaflow.

- Saw materials capability : Silicon, GaAs, Silicon Carbide, Copper wafers and Ceramic substrate, PCB.

|

LED Sawing Experiences

|

|

|

Purpose:

- We are able to perform Bevel Cut for special LED dies.

- Require additional breaking process

- Critical in control on un-cut depth (0.5mils) to prevent excessive chipping and double die during breaking

Criticalness Control on Un-cut Depth

- Tape thickness

- Table levelness

- Optimum setup parameter (Z height control)

|

Partial Sawing Experiences

|

|

|

- We are able to perform remount for broken wafer.

- We have SRU (Shape Recognize Unit) to define the shape of broken wafer to reduce the sawing time.

|

| Full Saw |

Partial Saw |

|

Substrate Sawing Experiences

Substrate Component

- Sawing on substrate contain of copper and encapsulant which having different co-efficient expansion.

Critical Criteria

- Copper frame burr and chipping

- Delam on transparent encapsulant

Criticalness Control on Sawing

- Optimum setup parameter (saw speed, define coolant angle, DI water flow rate)

- Chuck table levelness

- Selection of blade type (grit size, concentration range and exposure)

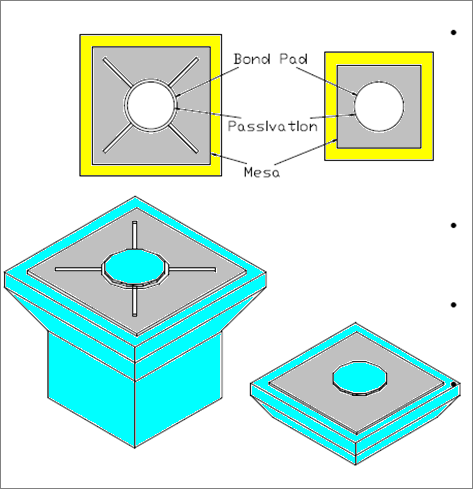

Side Braze Saw Experience

Sawing Concept :

- Engineering wafer to cut a structure out for assembly and testing.

Criticalness Control on Sawing

- Understand saw plan and manually program performing sawing.

Capabilities:

- Wafer thickness: thinnest down to 50 micron (2 mils)

- Saw street: as small as 0.8 mils

Sawing conditions capabilities:

- DI Water resistivity with CO2 bubbler <1M or >10M, RO, H2O2, Triton-X and Diamaflow.

Saw materials capabilities:

- Silicon, GaAs, Silicon Carbide, Copper wafers, Ceramic substrate and PCB.

Wastewater treatment capabilities:

| Capacity |

60 gpm |

| System Treatment |

Treatment Plant rinse water from Plating Bath, Sawing & Scrubber Wafer materials : Silicon, GaAS, InGaN, Silicon Carbite.

|

| Concentrate Areas |

Die and substrate Sawing STM Tin Plate & IDT Lines (Pump < 3,200litres/Month) |

| Operation |

24hrs/day |

Effluent Parameters:

To comply with Malaysian Environment Quality Act 1974 Standard B for the below parameters.

| Parameter |

Unit |

Limit For STD B |

| pH |

|

5.5 - 9.0 |

| BOD |

mg/I |

50 |

| COD |

mg/I |

100 |

| Suspended |

Solids |

100 |

| Tin |

mg/I |

1.0 |

| Lead |

mg/I |

0.5 |

| Nikel |

mg/I |

1.0 |

| Copper |

mg/I |

1.0 |

| Oil & Grease |

mg/I |

10.0 |

|